RESEARCH

Sensors

-

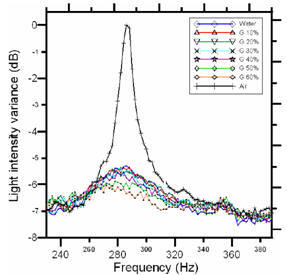

Optical viscosity and flow sensor (bendloss, polarimetric, Fabry-perot, forward scattering. etc.). The monitoring of fluid viscosity is a common analysis requirement in process industries. Timely, accurate and cost effective monitoring is often hindered by limits in viscosity sensor technology. We developed optical techniques for viscosity measurement optical using forward light scattering.

-

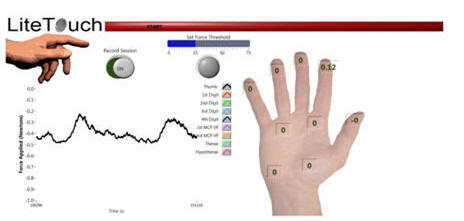

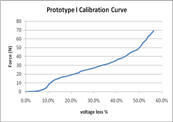

Clinical glove sensor. (microbendloss, electroactive polymer). To provide real-time quantitative feedback to clinicians, we have developed a disposable glove with a force sensor embedded in the fingertips or palm. The sensor is based on the fiberoptic bendloss effect whereby light intensity from an infrared source is attenuated as the fiber is bent between a series of corrugated teeth. The sensor fabricated has a very low profile (10 x 7 x 1 mm) and has demonstrated high sensitivity, accuracy, range, and durability. Forces as low as 0.1 N and up to 90 N have been measured with high signal to noise ratios.

-

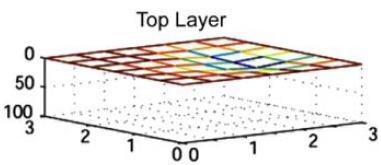

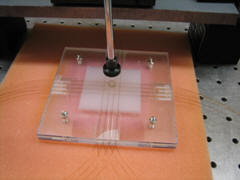

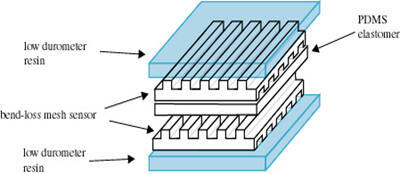

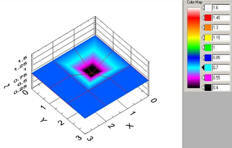

Distributive pressure/shear sensor (bendloss, optical gratings, low period grating, OTDR, etc.). The current research is aimed at developing, fabricating and implementing a flexible polymer-based optical sensor for the measurement of plantar pressure and shear stress. Two-dimensional information is determined by measuring the loss of light from each waveguide. Knowing which waveguide along the x-axis dims and one on the y-axis dims, the position of the waveguides gives the x and y coordinates of the pressure point. The shifting of the two layers relative to each other allows for the determination of the shear stress in the plane of the sensor.

- Current/magnetic field sensor

- Fourier transform spectrometer

- Broadband spectrometer (AWG, MZI, FTIR)

-

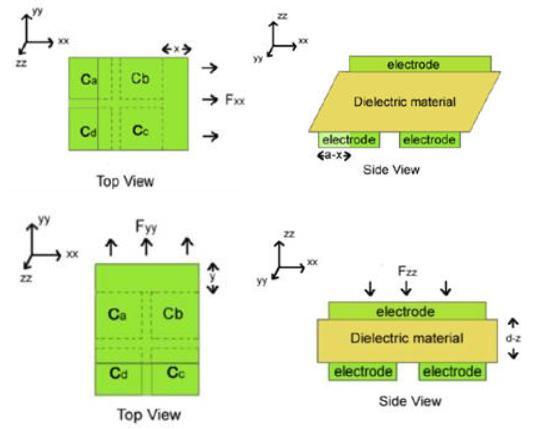

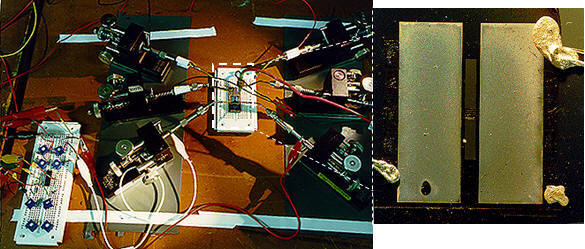

Polymeric 3-D tactile sensor. The tactile sensor comprises of a flexible quad capacitor array where three axial forces can be measured from the sensors’ relative areas and gap distances changes using a simple differential equation. The area of the sensor is less than 1x1 cm2 and the sensor is capable of detecting forces in any arbitrary direction with a sensitivity of 0.1 N and a force range up to 45 N. Video

-

Shockwave sensor. Here is the brief introduction to the project: Laser Diode sends light of known wavelength to sensor.Vibrations in sensor translate to changes in wavelength.Light frequency detected by Photo Diode.Photo Diode readings interpreted by LabView software.

-

MEMS based low frequency acoustic Hotwire sensor. Ideally suited for detecting the pressure wave originating from explosives, artillery, gunfire, or other sources. Once identified, the location of the target can be established. Advantages over traditional acoustic transducers include an ultra low frequency response(<1Hz) and directional sensitive. Compact yet rugged micro-fabricated design suitable for adapting to a variety of systems and for portable use in any hostile environment.

-

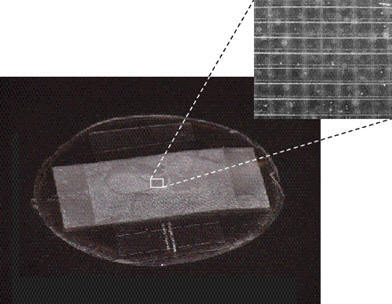

Micromachined waveguide sensor. The uniqueness of the system is in its batch fabrication process, which involves a microfabrication molding technique with polydimethylsiloxane (PDMS) as the optical medium. A flexible high-resolution sensor capable of measuring the distribution of pressure beneath the foot via a microfabricated optical waveguide system.

-

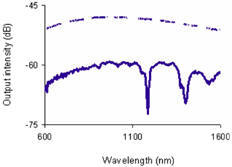

Grating sensor design. Strain at the locations of the gratings is determined by monitoring the shifts in wavelength of reflected signal from the perturbed gratings. Shear pressure can be derived based on relative changes in these optical strain gages. Our experimental results show that the polymer sensor is capable of measuring a small axial load and a shear load of 0.05 N. It is our expectation that a tensile shear sensor will be derived from the concept presented here for mechanical or biomedical applications.